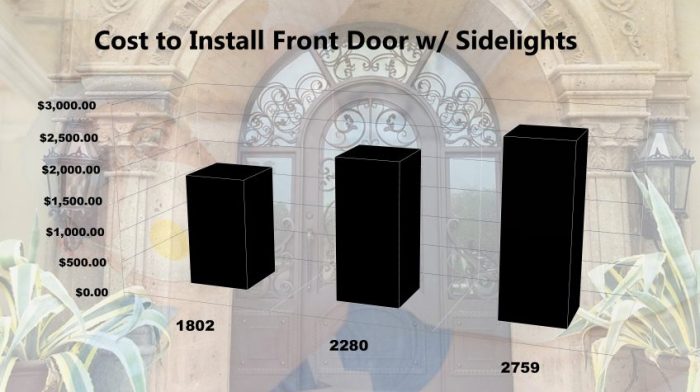

Costs to Install Front Door with Sidelights 2021

On average, the cost to install a front door with sidelights is about $2,280 with costs ranging from $1,802 to $2,759 in the US for 2021, according to HomeWyse. This front door installation cost estimate includes: The cost of material, equipment, and transportation The cost of preparing the site for front door with sidelights installation The…