A wrought iron railing helps to increase safety, preventing people, especially pets and children from falling off decks, stairs, balconies, or other elevated areas. Railings are commonly used on porches, catwalks, and other places people tend to spend time above ground level. We can help design, fabricate and then install the wrought iron railings you want and help prevent injuries due to a fall.

Experience is needed to fabricate wrought iron staircase railings, using welding techniques, practice and special tools. These are just the basics of what is required when creating wrought iron railings.

FABRICATING WROUGHT IRON STAIRCASE RAILINGS

What Makes A Staircase Railing?

Typically, a wrought iron staircase railing is created with panels. They are often rectangular, but metalworkers can create creative and customized railings. The panels are designed for installation on existing walls, newel posts, or other types of features.

There are four basic staircase railing sections:

- Balusters – These are vertical parts which commonly go between the bottom and top railing. The balusters purpose is to prevent pets and children from falling by not allowing access under the top railing.

- Top and bottom railings – These are the staircase railings backbone. These are the parts which hold balusters in position. They also allow people to rest on them for balance and support.

- Newel posts – These are vertical anchors which are placed in the home’s structure to offer staircase railings additional support. Newel posts are created using either wood or metal.

- Termination plates – These are the locations the end of railings is secured to architectural elements, such as walls.

Building Wrought Iron Staircase Railings To Code

As with most modern construction, staircase railings also have codes which must be followed. There are specific codes for each municipality regarding the construction of staircase railings. The majority of staircase railings require a certain height, usually around 36-inches to 38-inches from top to bottom railing. Many codes require a gap between the staircase surface and bottom railing. Typically, this gap will be around 3-inches.

To ensure the safety of small children and pets, balusters are generally spaced a max of 4-inches on the center. This means, measurements do not go from material edge, but from the center of each baluster. Depending on the fabricator, some prefer to make wrought iron staircase railings with smaller gaps between the balusters for additional safety. While this means more balusters are used, the additional cost is worth the safety precautions.

The codes regarding strength of staircase railings often state railings must have the ability to support a constant weight of 50lb per linear foot. Meanwhile, they have to withstand concentrated loads of at least 200lbs to ensure railings will support an adult that may have lost balance. These strengths are simple to attain using proper welding techniques.

Designing Wrought Iron Staircase Railings

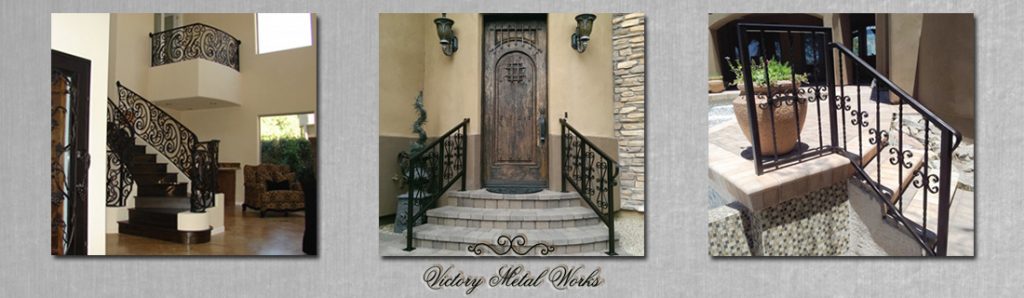

In this stage, the builder is able to use their imagination and get creative. When it comes to design styles, there are no limits. There is an endless amount of customization and detail work which can be applied to make the railings fit the style of a home or business. With today’s technology, clean minimalistic lines can be used for an ultra-modern design. If you desire, a more traditional style can be achieved as well.

There are various homes featuring staircases that were fabricated using creative metal artists. With an experienced metal artist, wrought iron staircases can become a one of a kind art piece that includes fascinating and unique details. The metal has the ability to be crafted to resemble natural elements, which can provide your home with warmth.

When you work with a professional designer and fabricator with experience the overall process can be simplified. Although, when having full creative control is an exciting part of the process, and doing your own welding can provide you full range.

Welding Wrought Iron Staircase Railings

There are various styles, methods, and equipment used for welding. There’s MIG welding, TIG welding, ARC welding, stick welding, among others. It does not matter what type of welding you decide to use for the wrought iron staircase railing, the important factor is that it is holding all the parts in position as they are welded. If you’re new to welding with little to no experience, it is best to get instruction and training by a qualified trainer prior to starting the project. This teaches the various elements of electricity, gasses, and heat used in welding, which need to be considered to prevent things from becoming dangerous.

When welding the wrought iron staircase railing, you’re going to follow the determined design by laying all components out in a safe, wide work space. From here, you begin securing each part together using your welding clamps. This is what holds the various parts together while welding.

Custom Wrought Iron Staircase Railings In Phoenix AZ

When you want a customized or detailed wrought iron staircase railing, Victory Metal Works is here to help eliminate the guess work when it comes to the design and fabrication process in the Phoenix region. We offer our services to the Phoenix Valley area, but the fabrication shop is located in Scottsdale. If you’re considering having a custom wrought iron staircase installed, give our experienced professional wrought iron team a call. We can assist with the whole project, from design, fabrication to the installation. Call today at 480-584-6220 or visit our shop at 8350 E. Evans Rd. Suite B-2 in Scottsdale.

SCHEDULE A FREE CONSULTATION TODAY!

Victory Metal Works is Arizona’s leading manufacturer of custom wrought iron Entry Doors, Gates, Railings, Fences, Hardware and much more in Scottsdale, Paradise Valley and the Greater Phoenix area. Our experience in the construction industry allows us to make your dreams become a reality. Call us at 480-584-6220 to get your next project started today!